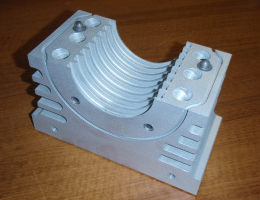

Our client presented us with a supply issue they had sourcing components used to manufacture Corrugated Pipe. Due to the short time constraint to supply their product to market, they could not wait the usual lead time from their international supplier. The client was only able to supply a sample part, without access to Drawings.

CHALLENGE

SOLUTION

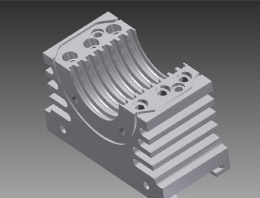

Working with the client, we used Autodesk Inventor Product Design Suite to accurately 3d model the sample part, and confirm final machining tolerances to ensure that the components would provide our client with the quality moulded product they expect.

This 3d model was quickly converted to a complete set of manufacturing drawings, and used with our MasterCam Cad/Cam software to efficiently produce CNC machine programs.